Premier Aluminum Llc for Dummies

Premier Aluminum Llc for Dummies

Blog Article

Getting The Premier Aluminum Llc To Work

Table of ContentsWhat Does Premier Aluminum Llc Do?The Greatest Guide To Premier Aluminum LlcGetting My Premier Aluminum Llc To WorkThe Basic Principles Of Premier Aluminum Llc

(https://wi-racine.cataloxy.us/firms/www.premieraluminum.com.htm)Making use of reduced price and unqualified suppliers can create high quality concerns, and threw away time and cash in the lengthy run. To assist you via the process, here are some things to take into consideration when selecting the best metal spreading vendor.

For instance, a company that just utilizes the financial investment spreading procedure will certainly try to sell you on why that process is best for your application. What if utilizing the sand casting procedure is best for you and your needs? Instead, seek a distributor that uses a variety of casting procedures so the finest option for YOU is picked

If functioning with a single resource for every one of your casting requires is necessary to you, the distributor requires to be varied in its capabilities. When combined with various other integrated capabilities, this can help simplify and compress the supply base. When selecting the best spreading vendor, cautious consideration should be offered to top quality, service, and price.

Premier Aluminum Llc Fundamentals Explained

Customers increasingly choose spreading providers who have machining abilities. This can avoid problem if flaws are uncovered during machining. If a third party is machining, it might cause "finger-pointing" about that is at fault. Is it a spreading problem or a machining problem? If the casting distributor uncovers an issue throughout machining, the problem is settled faster without any disagreement over whose mistake it is.

What do you require from your spreading supplier? Are you looking for someone to simply deliver a steel part to your doorstep or do you require much more?

Some factories are minimal or specialized. Make sure the provider can satisfy all your product or alloy demands to get rid of the requirement for numerous vendors.

The Best Guide To Premier Aluminum Llc

Research the vendor's internet site. Talk with a sales rep or service associate. Ask a whole lot of concerns. See their center. Get an understanding of what they can do for you and if you can see yourself developing a strong, mutual relationship with them.

Light weight aluminum is additionally lightweight and has good corrosion resistance, making it excellent for applications where weight and durability are necessary variables. Additionally, light weight aluminum casting is a cost-efficient method of manufacturing, as it needs much less energy and sources than other approaches. Iron casting, on the other hand, entails pouring molten iron right into a mold to produce a preferred shape.

Getting My Premier Aluminum Llc To Work

Iron casting is likewise able to hold up against high temperatures, making it appropriate for usage in applications such as engine parts and commercial machinery. Iron casting can be extra pricey than light weight aluminum casting due to the greater expense of raw products and the energy required to thaw the iron. When choosing between aluminum casting and iron casting, it is very important to take into consideration the certain requirements of the application.

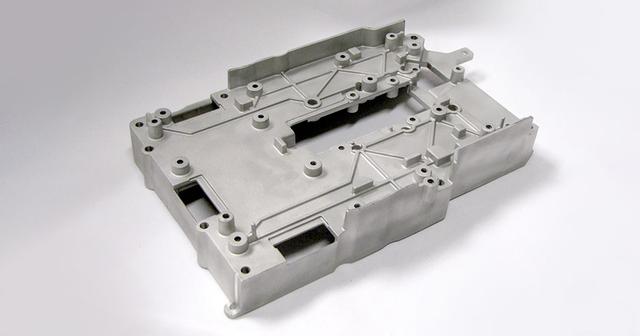

In final thought, both light weight aluminum spreading and iron spreading have their own unique benefits and disadvantages. There are three sub-processes that fall under the classification of die spreading: gravity pass away spreading (or irreversible mold and mildew spreading), low-pressure die casting and high-pressure die spreading. To get to the completed product, there are three primary alloys utilized as die spreading product to pick from: zinc, light weight aluminum and magnesium. Report this page